How does the 2022 war in Ukraine affect the global supply chain?

What is the Russia-Ukraine conflict?

Russian leader Vladimir Putin attempted to invade Ukraine, which unleashed the most significant war in Europe since World War Two. His justification is that Western-leaning Ukraine is a constant threat to Russia’s safety, development and existence.

Since Russia’s troops started bombing towns and residential areas, thousands of people have died, and over 13 million people have been displaced from their homes.

What is the Global Supply Chain?

As we know, our daily Apple iPhone is designed in California, assembled in China, and sourced from 43 different countries. It is done by utilising what we call the Global Supply Chain.

The supply chain is the action of sourcing goods or services from multiple manufacturers or providers to create a product and offer it to a consumer. As opposed to local, a global supply chain is a sourcing technique that takes advantage of sourcing products or services from low-cost countries worldwide to reduce the end product’s price.

Due to its complexity, the Global Supply Chain is sensitive to logistics, political situations, different cultures in different countries, local government labour laws, pandemics, and conflict situations, such as war, which we will try to address here.

Increased product shipping prices due to imposed sanctions

Sea freight prices already have tripled over a year due to global manufacturing and supply strain, mainly caused by the COVID-19 pandemic. The war in Ukraine will most likely only put even more pressure on these prices, which we, the consumers, see as our living costs rising.

As shipping companies suspend services to Russia to avoid breaching the sanctions imposed by Western-leaning countries, the global shipping routes become very volatile, directly affecting the global supply chain. The constrained shipping services cannot take advantage of wholesale pricing, causing the increased freight rates worldwide. Rising risk premiums to go into Northern Areas of Europe are also one of the leading causes of excessive shipping rates to these parts of the world.

Russia is the biggest oil producer, with about 10 million barrels daily. The economic sanctions resulted in soaring oil prices, which caused logistics prices to go up as oil is typically what powers massive sea container ships.

When land shipping is compromised by either conflict in the area or labour shortage, the suppliers might choose sea shipping; however, it is under stress already because of the pandemic.

Air shipping might come to save the day, however, probably only temporarily as to its high costs driving the product cost up, and manufacturers can only take a limited hit on their profits before raising the prices for end consumer. In addition, the air shipping routes are also affected by sanctions and no-fly zones, which only add up to operational hours, further driving the transportation costs up.

Critical element shortage in semiconductors manufacturing

Essential minerals are in shortage for car manufacturing due to them coming from Eastern Europe, and instability impacts the export of those minerals. There isn’t exactly a shortage of minerals to mine; however, alternative supply options will have to be explored, which is China, and we rely way too much on China already. With the country’s latest developments and prioritisation of internal markets over export, relying on China long-term could be problematic.

We have a disruption to vehicle manufacturing in Germany due to the country being involved in relations with both countries created a ripple effect, which we feel across the globe.

The semiconductor industry is also bracing for even more disruption. Russia accounts for 14% of the aluminium outcome. The country is also an essential source of titanium, platinum, and palladium, which are crucial ingredients in producing computer chips.

Russia and Ukraine are also significant sources of C4F6 and neon gases used in lasers vital to producing semiconductors. Reuters states that 45% to 55% of the world’s chip-grade neon manufacturing gases come from two Ukrainian companies, Ingas and Cryoin. Unfortunately, both companies had a disruption in production due to the escalation of Russian troops in the cities throughout Ukraine.

Other effects due to disruption of people’s welfare

Not only electronic equipment supply chains are affected. As Ukraine is a high producer of wheat products, consumers will face wheat product-based price increases. Last year, Ukraine produced about 33m tonnes of wheat, of which it exported about 20m tonnes, making it the sixth-largest exporter globally.

Sanctions against Russia are causing ripple effects. The most noticeable effects are within the oil, gas and coal industries. China indicated that from their perspective, the sanctions are an overstep. It resulted in further threats of sanctions on China if they chose to get involved in some kind of collaboration with Russia. If we have to sanction China, on top of the current sanctions for Russia, we will have closed off a considerable part of the world for our supplies and markets to sell our products.

The United Kingdom plans to phase out Russian oil by the end of 2022. This ambitious plan caused a shocking increase in utility bills resulting in some businesses considering even shutting down.

Challenges of integrating the displaced refugees into economies

Labour capital, which are the refugees that have been displaced from Ukraine due to war, could potentially take some pressure off the labour shortage in Europe as 3.5 million people have left the Ukraine. However, the problem is that around a third of them are children and the other two-thirds are primarily women.

European countries try to integrate them into the local economy by issuing working permits and special visas; however, they face issues such as lack of language, certifications and the fact that mothers prioritise the welfare of their children over putting many hours into work. The refugees also look at this relocation as a temporary solution and are not inclined to integrate into communities by learning the language or acquiring certifications.

The expectation of refugees solving the demand for the workforce within Europe might relieve some pressure from the situation; however, the effect is not to be seen in the short term future. There are 20 million refugees worldwide right now, and the average length of time they stay a refugee is 17 years, which is a toll on any country’s resources, including supply chain infrastructure.

How to improve response to disruption?

Improve resilience and decrease the pressure on your business’s supply chain by locally improving your product return recycling process. The best strategy is to optimise your return product stream as this is already a manufactured product, which in most cases simply needs to be repackaged and can be introduced back into saleable inventory.

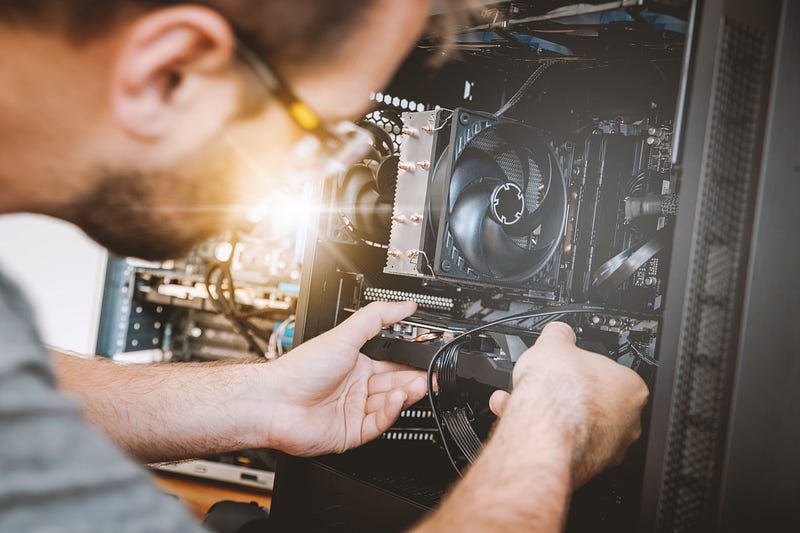

In electronic equipment sales, returns processing can be a bit more complicated due to the repair and testing required to ensure the product’s functionality. In such cases, you might require expert help. Companies such as TFix offer electronic equipment returns processing services and can take over the entire return cycle. It involves initial client query, providing free-to-customer send-in labels, updates, repair, testing, logistics and even storage. Services even include asset recovery or environmentally safe disposal of the beyond repair products.

Nearshoring or even homeshoring is a another supply chain resilience improvement strategy. It is the option of bringing production closer to its end or destination point. It might help to mitigate some of the shipping, tariffs and duty fee-related costs and gain more control over rising labour costs in the Far East and China.

Building new alliances with emerging markets, such as African and South American regions and the newly emerging world factory, India, are sensible choices to future proofing your supply chain.

Every problem is an opportunity to improve

Russia’s invasion of Ukraine causes tremendous distress in people’s lives and puts a lot of pressure on the global supply chain, which is crucial to keeping our living costs within what we can afford.

The global supply chain is disrupted due to increased shipping prices as companies struggle with sanctions, insurance premiums and oil prices. For example, economic sanctions on Russia’s oil supply caused soaring fuel prices in Western-leaning countries, which powers the big sea shipping containers, hence the high sea freight costs.

The semiconductor industry struggles to meet manufacturing demands due to a shortage of neon gas, critical to lasers used in chip production.

The displacement of people from Ukraine has put additional economic stress on European countries struggling to integrate them into local economies.

Businesses should look into alternative solutions to improve the resiliency of their production supply chain caused by this geopolitical situation.

Improving returned goods processing systems, bringing production closer to home and building alliances with emerging markets will help future-proof global markets.